- Home

- About Us

About Us

About Shine Engineering

Welcome to Shine Engineering

Shine Engineering was established in the year 2018 with a view of manufacturing high precision Sheet Metal Products for domestic as well as Industrial markets Like light & heavy fabricated products.

The promoters having a vast knowledge and experience of 20 years in the field of Sheet metal Industries.

It has started as a Small Scale Enterprise manufacturing Sheet Metal Components, Sub – assemblies for large OEM’s in the power generation , Auto industry, Oil – Gas , Pharma. And Furniture Industries.

We are engaged in manufacturing of sheet metal components for Oil & healthcare industries, Motors, Domestic Appliances, petrol bunk products and Assemblies etc.

Due to excellent quality in work, cost competitiveness, professionally skilled team, timely deliveries and state of the art manufacturing facilities, the company in a short span of time is a prime vendor to reputed OEM in domestic and Industrial market.

Our manufacturing facility is an ISO 9001 : 2015 certified by Otabu.

It has a good manufacturing facility and has the capability of producing high volume in specified time to the required quality specifications, customized to the requirement of the client as per their drawings / samples provided various operations like Punching , Laser Cutting, Bending, etc are carried.

Our Mission & Vision

- Our Mission

At Shine Engineering, our mission is to create engineering excellence through innovation, precision, and performance. We are dedicated to providing comprehensive and customized industrial solutions that not only meet but exceed our clients’ expectations.

We aim to transform challenges into opportunities by combining cutting-edge technology with unmatched technical expertise. Every project we execute is guided by our promise to deliver superior quality, reliability, and efficiency. Whether it’s mechanical design, fabrication, installation, or maintenance, we ensure that every detail reflects excellence, safety, and sustainability.

- Our Vision

Our vision is to be a global benchmark in industrial engineering — a company that sets new standards for innovation, sustainability, and performance. We aspire to be recognized not just for what we build, but for the values, trust, and transformation we bring to every partnership.

At Shine Engineering, we envision a world where engineering is more than a service — it’s a catalyst for industrial evolution. We see ourselves leading the way in designing smart, efficient, and eco-conscious systems that redefine productivity and reliability.

Our Values: Be a Honest , Ethical and transparent in business

Our Services

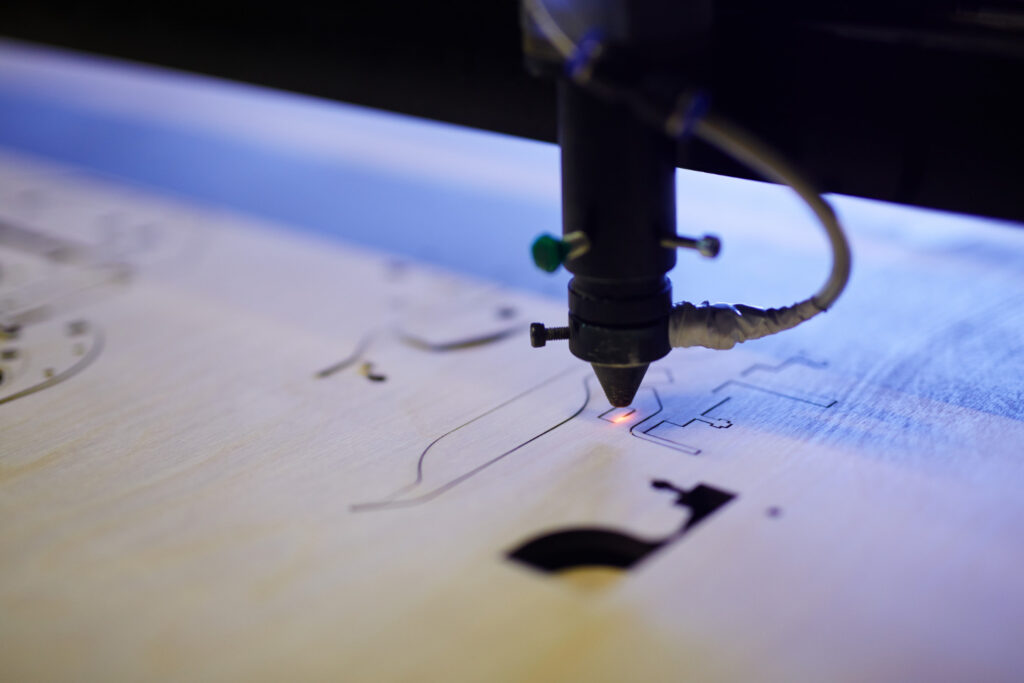

Laser Cutting

We use laser cutting technology which means using the laser to slice materials. We use this for manufacturing applications. Here laser cutting works by directing the output of a high-power laser mostly through optics.

Our Specifications:

- Tolerance: +/-0.1mm

- Thickness: Up to 20 mm(MS), Up to 12 mm(SS), Up to 8 mm(AL)

- Bed Size: Up to 1500 mmx 3000mm

- Laser Power: 3kw

Bending

We undertake bending works from our customers and use the latest CNC technology in order to meet our customer requirements. We handle the most complex and intricate bending services.

Our Specifications:

- Bending length – 2500 mm

- Capcity: 80 tons

- Control axis – 4 axis

- Frame Gap – 415 mm

Fabrication

We undertake fabrication works which are specifically the crafting of individual parts as a solo product or as a large combined product. We focus on stainless steel fabrication work, with the best methods with good quality.

Process Specifications:

- Laser Cutting

- CNC Bending

- Laser Welding

- TIG Welding

- Buffing, finishing

- Other supporting processes

Manufacturing facilities

| Machine Name | Make | Capacity | Qty |

|---|---|---|---|

| Manual Shearing Mc | Ideal Engg Mfg | 2mm | 1 |

| Laser Cutting Mc | Pride Laser | 3kw | 1 |

| Co2 – Welding | Power Arc | 300 A | 3 |

| TIG – Welding | GRB | 200 A | 1 |

| ARC – Welding | GRB | 200 A | 1 |

| Air Compressor | Vijay | 220 ltr | 1 |

| Buffing Mc | AEG | - | 1 |

| Hydraulic Press Break | Sri Hari Mc Mfg | 60 T | 1 |

| Drilling Machine | SEW | 1.5’’ | 1 |

Quality Policy & Objectives

Achieve Customer Satisfaction by Complying with the Customer Requirements & By Supplying Quality Sheet Metal Components through Continual Improvement in our Activities Relating to Product Manufacturing & Effectiveness of Quality Management System in the Organization.

- To meet the customer schedules

- To Monitor & reduce the total rejections and Customer. Complaints

- Continual Improvement Project to be taken from any Area.

- To provide training to the employee of the company

- To increase the sales of the company over the last year sales value

- To Develop more new components using the available facilities

- Development of the New customer.

Our Partners